The K24 propane idle assembly is an essential component in propane-powered engines, especially in applications ranging from automotive to industrial uses. Understanding the functionality, maintenance, and benefits of the K24 propane idle assembly can help users optimize their engines for better performance and longevity. This article delves into the workings of the K24 propane idle assembly, its significance, and how to maintain it for optimal performance.

What is the K24 Propane Idle Assembly?

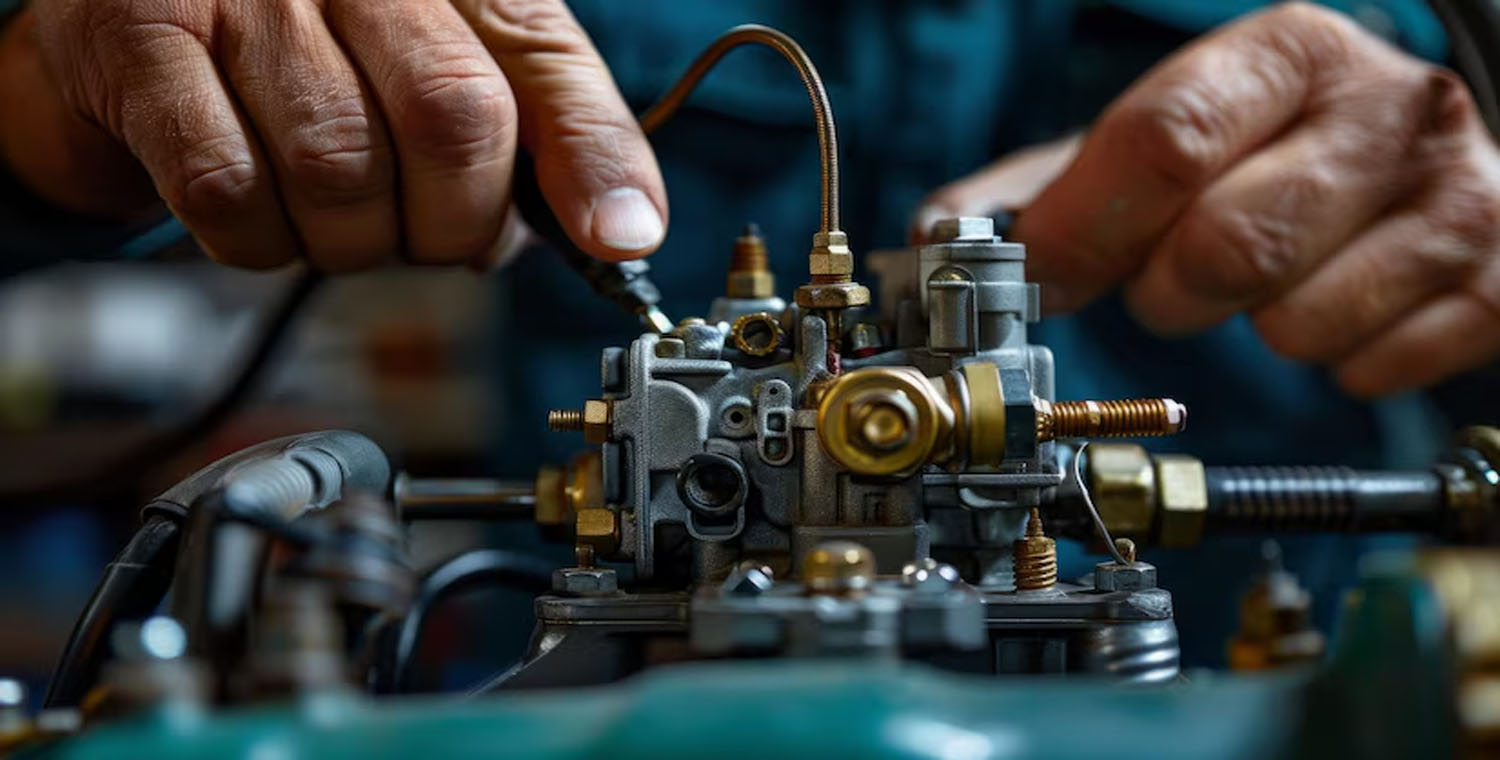

The K24 propane idle assembly is a critical part of a propane fuel system in engines, primarily designed for idle operation. This assembly regulates the flow of propane gas to the engine, ensuring that the fuel mixture remains optimal for efficient combustion while idling. Its primary role is to maintain a stable engine idle speed, which is crucial for smooth operation and minimizing emissions.

Key Components of the K24 Propane Idle Assembly

Understanding the components of the K24 propane idle assembly helps clarify its functionality. Key components include:

- Idle Air Control Valve (IAC): This valve regulates the amount of air entering the engine at idle. It ensures that the engine receives the correct air-to-fuel ratio for optimal combustion.

- Propane Injector: This component delivers propane to the engine’s intake manifold. Proper operation of the injector is crucial for efficient fuel delivery.

- Pressure Regulator: The pressure regulator ensures that the propane is delivered at the correct pressure to the injector. This component is vital for maintaining engine performance.

- Sensors: Various sensors monitor engine parameters such as temperature and pressure. These sensors provide feedback to the engine control unit (ECU) for fine-tuning the idle assembly’s performance.

- Control Module: The control module receives data from the sensors and adjusts the idle air control valve and propane injector accordingly. This ensures that the engine maintains the desired idle speed.

How the K24 Propane Idle Assembly Works

The operation of the K24 propane idle assembly involves several steps:

- Initial Startup: When the engine starts, the ECU activates the idle assembly. The pressure regulator adjusts the propane pressure, ensuring a consistent flow.

- Air-Fuel Mixture Regulation: The IAC valve regulates the airflow into the engine while the propane injector delivers the appropriate amount of propane. The ECU continuously monitors and adjusts these components to maintain an optimal air-fuel mixture.

- Idle Speed Maintenance: As the engine idles, the ECU adjusts the IAC valve and injector based on feedback from the sensors. This dynamic adjustment ensures that the engine runs smoothly at idle without stalling or surging.

- Monitoring and Adjustments: The control module constantly monitors the engine parameters. If any irregularities are detected, it makes real-time adjustments to the idle assembly components to correct them.

Importance of the K24 Propane Idle Assembly

The K24 propane idle assembly plays a vital role in engine performance and efficiency. Here are some of its key benefits:

1. Smooth Idle Operation

One of the primary functions of the idle assembly is to ensure smooth engine operation at idle. A properly functioning K24 assembly prevents stalling and ensures that the engine maintains a steady idle speed, contributing to overall vehicle comfort.

2. Fuel Efficiency

By regulating the air-fuel mixture accurately, the K24 propane idle assembly helps optimize fuel consumption. This efficiency leads to reduced operating costs, making it an essential component for businesses that rely on propane-powered equipment.

3. Emission Control

The K24 propane idle assembly helps maintain optimal combustion, reducing harmful emissions. This is particularly important for meeting environmental regulations and improving air quality.

4. Enhanced Engine Longevity

Regular maintenance of the K24 propane idle assembly can extend the life of the engine. By ensuring proper fuel delivery and combustion, the assembly helps reduce wear and tear on engine components.

Maintenance of the K24 Propane Idle Assembly

To ensure the K24 propane idle assembly operates effectively, regular maintenance is crucial. Here are some key maintenance practices:

1. Regular Inspections

Conduct routine inspections of the idle assembly components, including the IAC valve, propane injector, and pressure regulator. Look for signs of wear or damage and replace any faulty parts as needed.

2. Clean the Components

Over time, carbon deposits can build up on the IAC valve and propane injector. Regular cleaning of these components can prevent blockages and ensure optimal performance. Use appropriate cleaning solutions recommended for propane systems.

3. Check the Sensors

Ensure that the sensors connected to the K24 propane idle assembly are functioning correctly. If the sensors are faulty, they may provide inaccurate data to the ECU, leading to poor engine performance. Replace any malfunctioning sensors promptly.

4. Monitor Fuel Quality

The quality of propane fuel can impact the performance of the idle assembly. Ensure that you are using high-quality propane free from impurities. Contaminated fuel can lead to injector clogging and other issues.

5. Consult the Manual

Always refer to the manufacturer’s manual for specific maintenance recommendations for your K24 propane idle assembly. Following the guidelines provided can help prevent issues and maintain optimal performance.

Troubleshooting Common Issues

Despite regular maintenance, issues can arise with the K24 propane idle assembly. Here are some common problems and their solutions:

1. Rough Idle

If the engine experiences a rough idle, it could be due to a malfunctioning IAC valve or improper air-fuel mixture. Check the IAC valve for blockages or wear, and clean or replace it as necessary.

2. Stalling

Stalling at idle may indicate a problem with the propane injector or pressure regulator. Inspect these components for proper function and ensure they are delivering the correct amount of fuel.

3. High Idle Speed

If the engine idles too high, it may be due to a stuck IAC valve or incorrect sensor readings. Check the IAC valve for proper operation and replace any faulty sensors that may be affecting the ECU’s adjustments.

4. Low Power Output

If the engine lacks power while running, the K24 propane idle assembly may not be delivering the correct air-fuel mixture. Inspect the assembly for blockages or malfunctions and make necessary adjustments.

Conclusion

The K24 propane idle assembly is a crucial component for ensuring the smooth operation and efficiency of propane-powered engines. Its role in regulating the air-fuel mixture and maintaining a stable idle speed cannot be understated. By understanding its functionality, performing regular maintenance, and troubleshooting common issues, users can optimize their engine’s performance and longevity.

More Read: